Table of Contents[Hide]

- 1. Understanding the taxonomy: three levels of suiting

- 2. The fundamental problem with off-the-rack suits

- 3. How made-to-measure works: the technical process

- 4. The fit bible: how a suit should actually fit

- 5. The economic truth: cost-per-wear analysis

- 6. Construction deep dive: what you're actually paying for

- 7. Body-type specific fit guide

- 8. When to choose MTM vs when to choose OTR

- 9. The MTM process: what to expect with Dunnio Tailor

- 10. Can off-the-rack suits be tailored? Realistic expectations

- 11. Fabric and seasonal considerations

- 12. Special use case: the wedding suit decision

- 14. How to get started with Dunnio MTM

- 15. Frequently asked questions about made to measure vs off the rack suits

Buying a suit shouldn't feel like choosing between perfection and bankruptcy. Yet most men face this exact dilemma: settle for an ill-fitting off-the-rack suit that bunches at the shoulders and gaps at the collar, or invest $5,000+ in traditional bespoke tailoring. There's a smarter middle ground: made-to-measure suiting that delivers precision fit at accessible prices ($144-$600). This comprehensive guide decodes the real differences between MTM and OTR suits, reveals hidden costs, and shows how body-type-specific tailoring solves fit challenges that standard sizing can't. Whether you're a groom seeking wedding perfection, an executive building a professional wardrobe, or simply tired of suits that never quite fit right, discover why modern MTM has become the definitive choice for discerning men worldwide.

1. Understanding the taxonomy: three levels of suiting

The suiting world operates on three distinct tiers,each representing different intersections of cost, time, and fit precision. Understanding these categories is essential before making any purchase decision about made to measure vs off the rack suits for men.

Off-the-rack suits, also called ready-to-wear, are mass-produced garments manufactured in standard sizes based on average body templates. Walk into any department store and you'll find racks organized by chest measurements like 38R (38-inch chest, regular length) or 42L (42-inch chest, long length). These suits are designed for immediate purchase and wear, making them the default choice for men facing urgent needs or working within tight budgets. However, the fundamental limitation lies in their one-size-fits-many approach. Standard sizing assumes your chest, waist, sleeve, and shoulder measurements all correspond to a predetermined ratio, which rarely matches real human body diversity.

Made-to-measure suits occupy the strategic middle ground between mass production and full bespoke. Rather than creating a pattern from scratch, MTM starts with a proven base pattern that gets adjusted according to your specific measurements. A proper MTM consultation involves recording 25 or more body dimensions including shoulder slope, arm pitch, posture characteristics, and asymmetries that standard sizing completely ignores. You also gain extensive design control over fabric selection (from hundreds of options), lining colors, lapel styles, button configurations, and finishing details. Modern MTM leverages digital measurement technology and established production systems to deliver custom-fitted suits in 4-8 weeks at prices ranging from $144 to $3,000 depending on fabric quality and brand positioning.

Bespoke represents the pinnacle of tailoring craftsmanship. A bespoke tailor creates an entirely unique pattern drawn specifically for your body, requiring multiple intermediate fittings as the suit progresses through construction stages. This process typically involves 2-3 fitting sessions over 8-12+ weeks, with master tailors making continuous adjustments to achieve absolute precision. Bespoke remains the domain of heritage tailoring houses, particularly those on London's famous Savile Row, where prices typically start at $5,000 and can exceed $15,000 for the finest materials and craftsmanship.

Comparison of suit types

| Feature | Off-the-rack | Made-to-measure | Bespoke |

| Production | Mass-produced in stock | Made-to-order from template | Hand-made from scratch |

| Pattern mechanics | Standard size blocks | Adjusted base pattern | Unique individual pattern |

| Fit precision | General/average | Tailored to body and posture | Absolute precision |

| Customization | Minimal/limited | High (fabric, lining, lapels) | Maximum (limitless) |

| Wait time | Immediate (same day) | 21 days (3 weeks) | 8 to 12+ weeks |

| Construction | Often fused (glued) | Floating or half-canvas | Full canvas/hand-padded |

| Typical price (USD) | $200 to $800 | $1,000 to $3,000 | $5,000+ |

For most men seeking the balance of quality, fit, and value, made-to-measure suits provide the optimal solution. You can explore custom suits at Dunnio Tailor starting at just $144, or visualize your perfect fit using the 3D suit configurator before committing.

2. The fundamental problem with off-the-rack suits

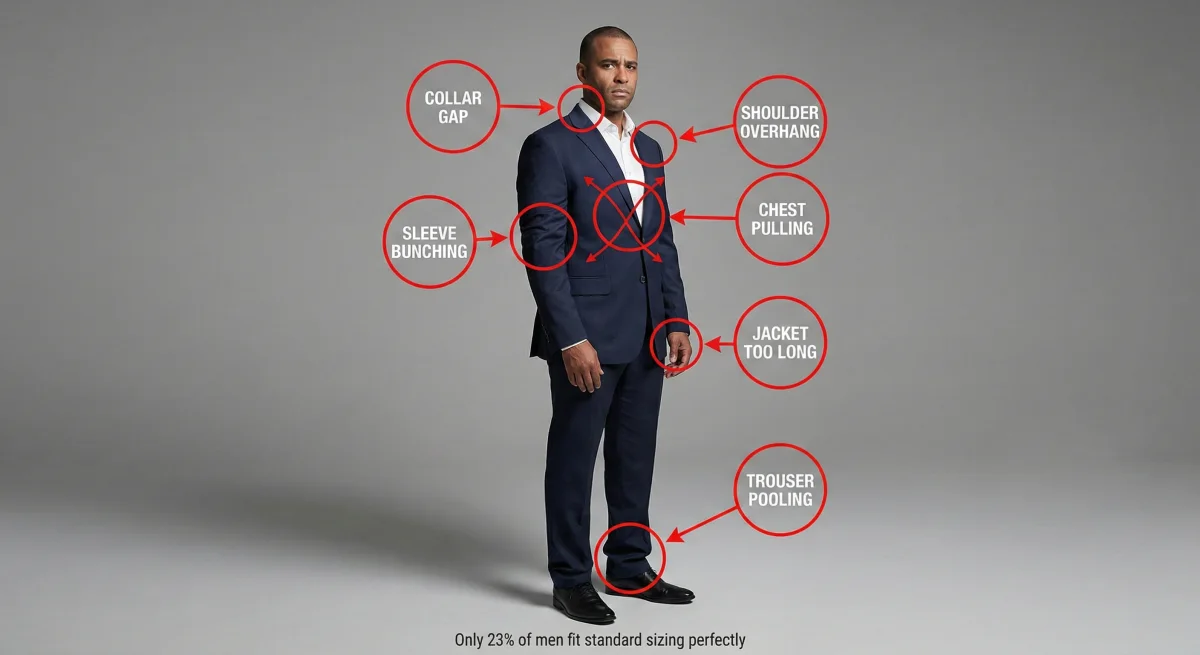

The core issue with off-the-rack suiting is the standardization trap. Clothing manufacturers create sizing templates based on average measurements derived from population studies. While this approach allows efficient mass production, it creates a paradox: average measurements fit almost no one perfectly because human bodies exhibit extraordinary diversity in proportions, posture, and asymmetries.

Common fit issues with rack suits include:

- Collar gaps: The jacket collar pulls away from your shirt collar at the back of the neck, creating an unsightly gap. This occurs when the neck-to-shoulder relationship doesn't match the standard pattern.

- Chest stress or excess: Athletic builds often experience pulling across the chest when the jacket is buttoned, while leaner builds find excess fabric creating a billowing effect.

- Sleeve bunching: Fabric bunches at the bicep or forearm because the sleeve width doesn't account for your arm musculature or the natural forward pitch of your arms.

- Trouser fit mismatches: Finding pants where the waist fits correctly often means the thighs are too tight or too loose, and the rise (distance from crotch to waistband) rarely matches your torso length.

- Jacket length imbalance: Standard "short," "regular," and "long" designations add or subtract overall length but don't adjust the proportional relationship between jacket components.

For men with body types that deviate from the narrow standard, these issues multiply. Consider big-bellied men who need suits off the rack. Sizing up to accommodate waist circumference results in shoulders that are far too wide and sleeves that hang past the wrists. Sizing for the shoulders creates painful tightness around the midsection. No amount of basic alterations can reconcile these competing needs because the fundamental pattern doesn't account for independent chest versus waist measurements.

Research in anthropometrics (the study of human body measurements) reveals that only about 23% of men fit comfortably into standard off-the-rack sizing without requiring significant alterations. The remaining 77% must either accept compromised fit or invest $150-$300 in professional tailoring to address the most obvious issues. Even with alterations, certain structural elements like shoulder width, armhole placement, and overall balance remain forever compromised.

This reality makes the comparison between tailored suit vs off the rack options increasingly relevant. When you factor alterations costs into the equation, mid-range off-the-rack suits often cost nearly as much as entry-level made-to-measure optionsbut still deliver inferior fit. If fit challenges particularly affect your trouser comfort, exploring custom pants with independent waist and seat measurements can resolve issues that standard sizing can't address.

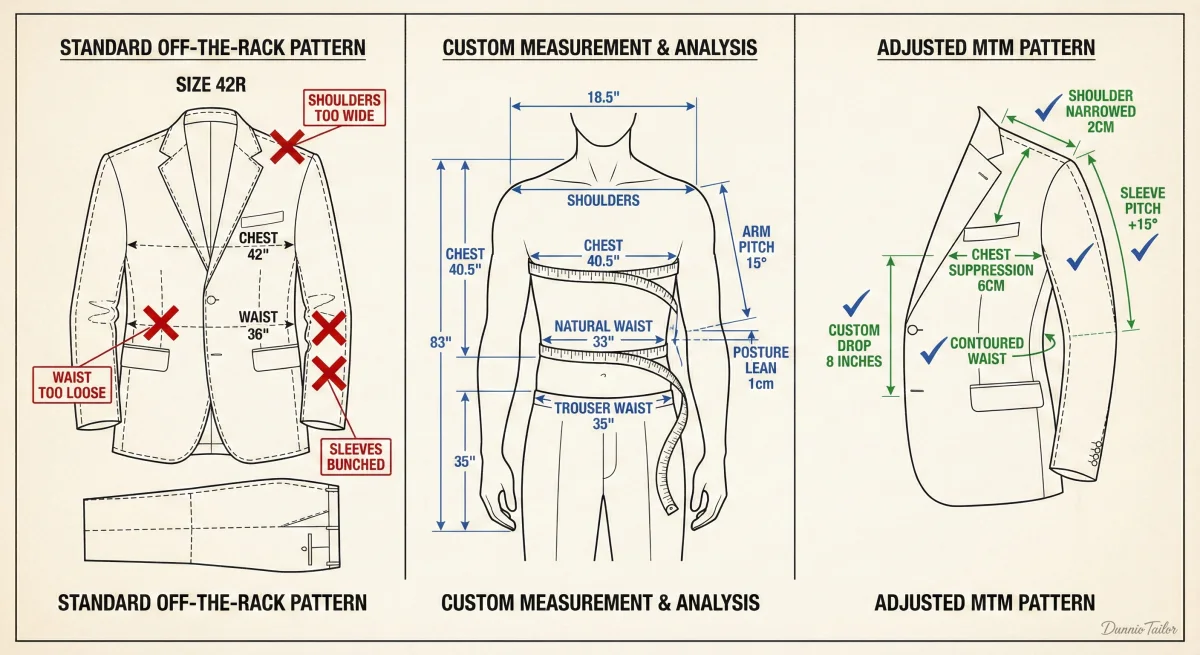

3. How made-to-measure works: the technical process

Understanding the MTM process demystifies what you're actually paying for when choosing made to measure vs off the rack suits. The process typically unfolds in six distinct phases.

- Initial consultation: This session establishes your style preferences, intended usage scenarios (business, weddings, formal events), and timeline requirements. A knowledgeable consultant will ask about your lifestyle, profession, and the specific occasions where you'll wear the suit. This information guides fabric recommendations and design choices.

- Precision measurement: Unlike off-the-rack shopping where a salesperson might simply measure your chest, proper MTM involves recording 25 or more body dimensions. These include obvious measurements like chest, waist, and inseam, but extend to nuanced details like shoulder slope angle, arm pitch (how your arms hang naturally), posture characteristics (whether you stand erect or have forward-leaning shoulders), and body asymmetries (most people have one shoulder slightly higher than the other, or one arm slightly longer).

- Fabric and design selection: Made-to-measure services provide access to hundreds of fabric options from prestigious mills. You'll examine fabric weights (measured in grams per meter), weave patterns, and composition (pure wool, wool-silk blends, wool-linen for summer, wool-cashmere for winter). Design customization includes lapel width and style (notch, peak, or shawl), button configuration (two-button versus three-button front), pocket styles, lining colors and patterns, and details like working buttonholes on sleeves or monogramming.

- Pattern modification: This is where MTM fundamentally differs from bespoke. Rather than creating a completely new pattern, the tailor selects the closest base pattern from their library and applies your specific measurements to modify it. Advanced MTM operations use digital systems that automatically calculate the necessary adjustments, while traditional tailors may make hand-drawn modifications to paper patterns. The goal is adjusting the template to accommodate your unique body characteristics.

- Construction: This phase showcases where premium MTM services differentiate themselves. Dunnio Tailor leverages Vietnamese artisan craftsmanship to deliver exceptional value. Our master tailors possess a natural precision advantage: smaller hands that can execute intricate stitching, detailed embroidery, and delicate construction techniques with exceptional accuracy. This combines traditional tailoring heritage with modern pattern technology, allowing us to deliver bespoke-quality construction at accessible MTM pricing.

- Quality control and delivery: After construction, each suit undergoes quality inspection before shipping. The entire timeline typically spans 4-8 weeks from initial order to delivery, though rush services may be available for additional fees.

The MTM process produces suits that fit your body from the first wearing rather than requiring extensive alterations. You can experience this precision by designing a custom jacket using Dunnio's 3D configurator, which allows you to visualize fabrics and details before committing. The result is a garment that not only fits correctly but also reflects your personal style preferences in ways that off-the-rack suits simply cannot match.

4. The fit bible: how a suit should actually fit

Understanding correct suit fit is essential when evaluating how are suit jackets supposed to fit and whether your current suits meet professional standards. Perfect fit involves multiple components working in harmony.

- Shoulders: The shoulder seam should end precisely where your natural shoulder ends. Run your finger along your shoulder from your neck outward until you feel the bone endthat's where the seam should sit. If the seam extends past this point, the shoulders are too wide, creating a droopy appearance. If the seam falls short and sits on top of your shoulder, the jacket is too tight, restricting movement and creating divots in the fabric. Because many men have slightly uneven shoulder heights, quality MTM accounts for this asymmetry by adjusting each shoulder independently.

- Chest and waist: When you button the jacket (never button the bottom button on a two- or three-button jacket), you should be able to slide two fingers comfortably between the fabric and your chest. The jacket should not pull across the chest when buttoned, creating an "X" of tension lines. Simultaneously, the jacket shouldn't billow away from your body when standing naturally. The waist should show some suppression (tapering from chest to waist) for a modern silhouette, with the degree of suppression depending on your build and style preference.

- Sleeves: Jacket sleeves should end at your wrist bone when your arms hang naturally at your sides. When wearing a dress shirt, approximately 1 to 1.5 centimeters of shirt cuff should be visible beyond the jacket sleeve. This detail signals attention to fit. Premium MTM and bespoke suits feature functional buttonholes on the sleeve cuffs (called working buttonholes or surgeon's cuffs), while most off-the-rack suits have decorative non-functional buttons.

- Jacket length: Stand naturally with your arms relaxed at your sides. The jacket hem should reach approximately the middle of your palm or the base of your thumb. This length ensures the jacket covers roughly 75% of your seat, creating balanced proportions. If the jacket doesn't cover your wrist completely, it's definitely too short. If it completely covers your fingers, it's definitely too long.

- Collar: The jacket collar should sit flush against your shirt collar at the back of your neck without any gap. Approximately 1 to 1.5 centimeters of shirt collar should be visible above the jacket collar. A collar gap (space between shirt and jacket at the nape) signals poor fit usually caused by incorrect shoulder slope or posture accommodation.

- Trousers: Pants should sit at your natural waist (where your torso meets your hips) without requiring a belt to stay up. The traditional "single break" means the fabric touches the top of your shoe and creates one small horizontal fold. Modern slim fits might have no break at all, with the hem just touching the shoe. Avoid excessive fabric pooling around the ankles, which creates a sloppy appearance.

Body-type-specific considerations:

- For tall and slim men: Standard "long" sizes simply add length without adjusting proportions. You need sleeve length without excess shoulder width, and leg length without baggy thighs. MTM allows these independent adjustments.

- For athletic builds: You need room in the chest, thighs, and seat without enormous waists. Standard sizing can't accommodate this ratio.

- For shorter men: Jacket length is critical. Standard "short" sizes are often still too long relative to your overall height, disrupting visual proportions.

Perfect fit isn't just aestheticit's functional. Properly fitted suits allow unrestricted movement, maintain their shape throughout the day, and project confidence and authority in professional settings. For occasions where fit perfection is non-negotiable, like weddings, custom wedding suits ensure you look your absolute best in photographs that last forever.

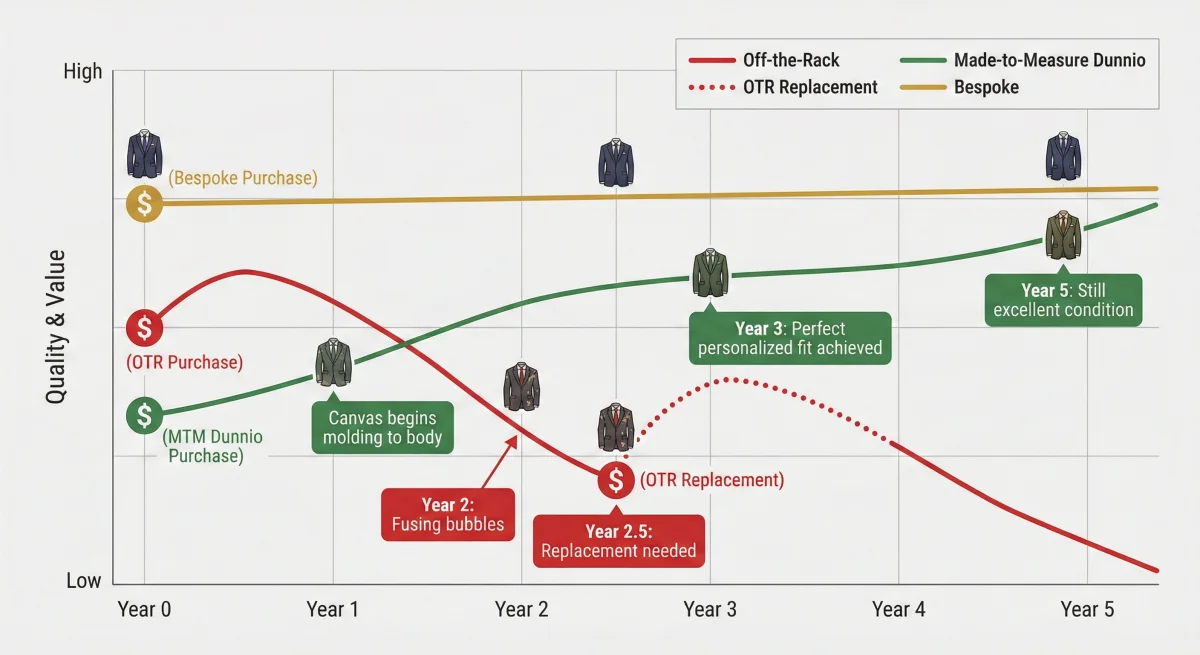

5. The economic truth: cost-per-wear analysis

The most rational approach to evaluating the cost of custom suits versus off-the-rack options is the cost-per-wear (CPW) formula. This calculation reveals the true economic value by dividing total ownership costs by the number of times you'll actually wear the garment.

The cost-per-wear formula: CPW = (Initial price + Alterations + Maintenance) divided by Number of wears

Consider two scenarios for a businessman who wears suits weekly (approximately 50 times per year).

Five-year comparison

| Expense item | Off-the-rack (mid-range) | Dunnio MTM | Western bespoke |

| Initial purchase | $500 | $400 | $5,000 |

| Professional tailoring | $150 | $0 | $0 |

| Replacement frequency | Every 2.5 years (2 times) | 10+ years (0 times) | 15+ years (0 times) |

| Five-year total spend | $1,300 | $400 | $5,000 |

| Cost per wear (50 wears/year) | $5.20 | $1.60 | $20.00 |

| Perceived value over time | Declining | Appreciating | Peak |

This analysis reveals several critical insights. First, MTM suits break even with off-the-rack options after approximately 75 wears. For men wearing suits weekly, this represents just 1.5 years. Second, the dramatic price difference between affordable MTM services like Dunnio ($144-$600) and traditional Western bespoke ($5,000+) demonstrates that geographic manufacturing location significantly impacts pricing without necessarily compromising quality.

Third, the "perceived value trajectory" differs dramatically. Off-the-rack suits decline in both function and appearance as fused construction begins to bubble, fabric pills, and compromised fit becomes more obvious. Quality MTM suits with canvassed construction actually improve over time as the horsehair canvas molds to your body, creating increasingly personalized fit. The fabric develops a subtle patina that signals quality rather than wear.

Dunnio Tailor's transparent pricing structure:

- Entry level suits: $144 (ideal for wedding party groups where multiple suits ordered together receive volume pricing).

- Premium fabrics: $300 to $450 (Twill - Technical, Oxford, Chambray, Barathea, Satin - Technical, Hapsack - Cotton Blend, Plain - Cotton Blend, Plain - Pure Linen, fabrics with extensive customization).

- Luxury mill fabrics: $500 to $600 (Twill - Wool Blends, Wool 150s).

Compare these prices to typical US and UK MTM services charging $1,200-$3,000 for comparable construction, or Savile Row bespoke starting at $5,000. You receive the same half-canvassed construction, precision measurement-based fit, and extensive customization at a fraction of traditional costs. This value proposition makes MTM accessible to professional men who previously considered custom tailoring financially out of reach.

For formal occasions requiring both aesthetic perfection and long-term value, custom tuxedos deliver better ROI than rental or cheap off-the-rack options. You can also visualize your tuxedo design using the 3D configurator before ordering.

6. Construction deep dive: what you're actually paying for

When comparing tailor made suit vs off the rack options, understanding construction quality explains why some $400 suits outlast $800 suits. The difference lies in internal architecture and materials invisible from the outside.

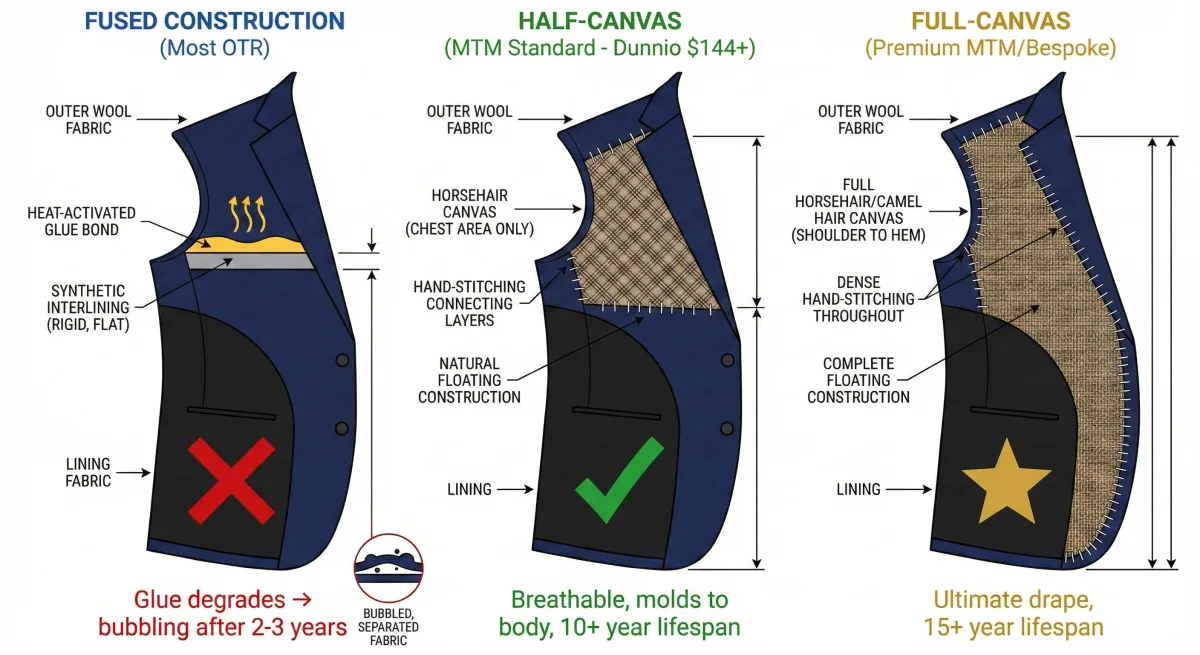

Fused versus canvassed construction comparison

Fused construction: Most entry-level and mid-range off-the-rack suits use fused interlinings. Manufacturers apply heat-activated adhesive to bond a stiffening layer to the outer suit fabric. This method is fast and cost-effective for mass production. However, the glue bond gradually degrades through normal wear, body heat, moisture, and especially dry-cleaning chemicals. After 2-3 years and 50-75 wears, fused suits develop "bubbling"visible ripples and separation between the lining and outer fabric that can't be repaired. The jacket must be replaced.

Half-canvas construction: This represents the minimum quality standard for MTM suits. A piece of horsehair or camel hair canvas is hand-stitched to the chest area of the jacket front, from the shoulder to roughly the bottom of the chest. This canvas "floats" between the outer fabric and lining rather than being glued. The canvas molds to your body shape over time while providing structure and allowing the jacket to drape naturally. The jacket breathes better because layers aren't sealed together. Half-canvas suits from Dunnio start at $144, making this construction method accessible to budget-conscious buyers.

Full-canvas construction: Premium MTM and all bespoke suits feature canvas extending from shoulder to hem throughout the entire jacket front. This requires significantly more labor as tailors must hand-stitch the canvas using traditional techniques. Full-canvas jackets achieve the ultimate in drape, breathability, and longevity, easily lasting 15+ years with proper care. The jacket essentially becomes a second skin that conforms to your unique body shape and posture.

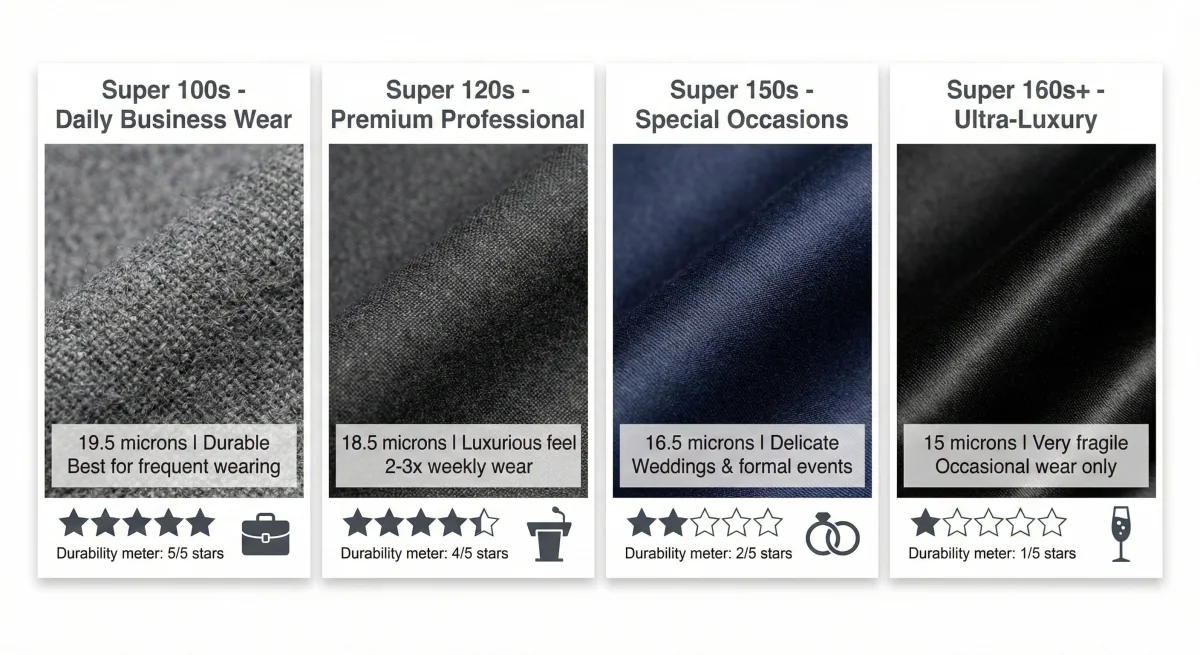

6.1. Fabric quality: understanding super numbers

- The "Super" number (Super 100s, 120s, 150s) indicates the fineness of wool fiber used in the fabric, measured by fiber diameter in microns. Higher numbers mean finer, softer fibers, but this creates a durability tradeoff.

- Super 100s to 120s: This range represents the sweet spot for daily business wear. The fabric feels luxurious and smooth while maintaining durability for frequent wearing. Super 120s can withstand regular use 2-3 times per week for years without showing excessive wear. Most quality MTM services, including Dunnio, offer extensive selections in this range.

- Super 130s to 150s: These ultra-fine wools provide exceptional softness and a subtle luster that photographs beautifully. However, they're more delicate and prone to wrinkling and abrasion. Reserve these for special occasions like weddings or important presentations rather than daily wear.

- Super 160s and beyond: These reach the limits of wool fineness and are extremely fragile. While luxuriously soft, they can develop shine from friction and may eventually tear from stress points. Only appropriate for occasional wear by those who understand and accept the maintenance requirements.

6.2. Natural blends expand your options:

- Wool-silk blends: Adding 5-15% silk creates subtle sheen and a springy texture ideal for wedding suits and formal occasions. The silk adds wrinkle resistance while maintaining breathability.

- Wool-linen blends: Summer destination weddings and hot-climate business require breathability. Linen additions create temperature regulation while the wool maintains structure. Explore linen wedding suit options for warm-weather ceremonies.

- Wool-cashmere blends: Winter suits benefit from cashmere's exceptional softness and warmth. However, cashmere is less durable than pure wool, so these suits require gentle handling.

6.3. What Dunnio offers in construction:

- Standard construction: Half-canvas in all suits starting at $144 entry price point.

- Premium construction: Full-canvas available in $300+ range.

- Fabric range: Twill - Technical, Oxford, Chambray, Barathea, Satin - Technical, Hapsack - Cotton Blend, Plain - Cotton Blend, Plain - Pure Linen and specialty mills (Twill - Wool Blends, Wool 150s).

- Customization: Independent selection of outer fabric, lining fabric, button materials, and stitching colors.

Notes:

- Additionally, you can also request other premium or specialty fabrics. Please contact Dunnio Tailor to place a custom order for your specific fabric requirements.

- This construction quality, combined with Vietnamese artisan precision in execution, allows Dunnio to deliver garments that compete with bespoke tailoring at accessible MTM pricing.

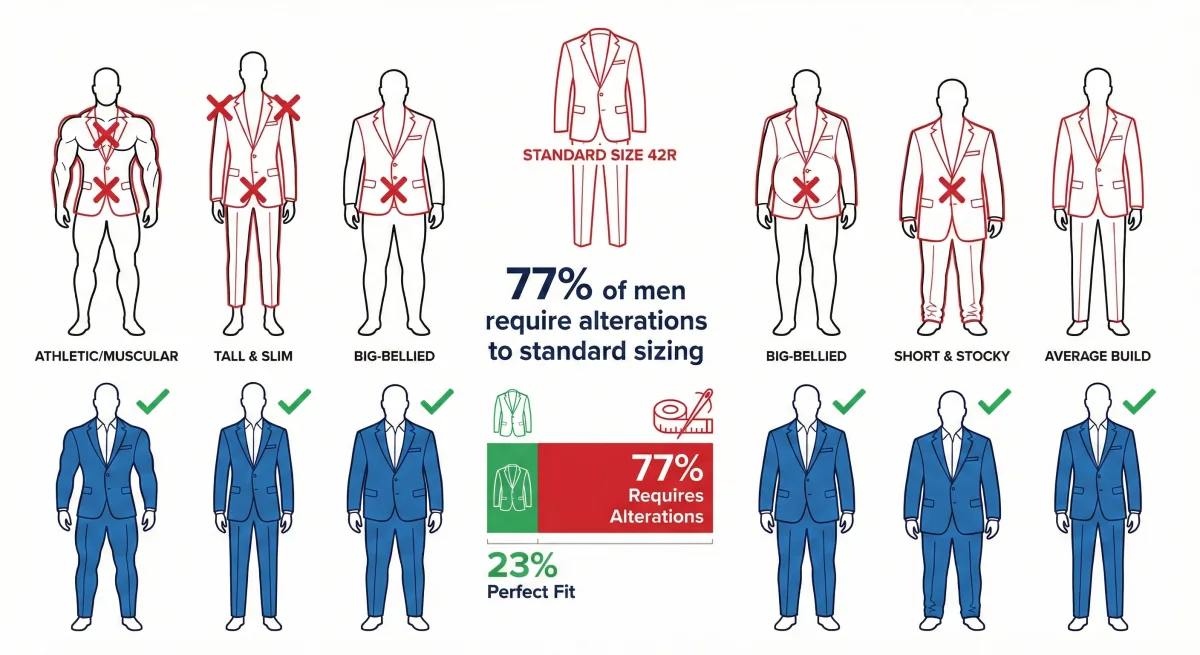

7. Body-type specific fit guide

This section addresses the most under-served audience in suiting: men whose bodies don't conform to standard sizing templates. Understanding how made to measure vs off the rack suits address specific body challenges helps you make informed decisions.

7.1. Made to measure vs off the rack suits for fat men

Common off-the-rack problems:

Standard sizing assumes your chest measurement predicts your waist measurement using predetermined formulas. For heavier men, this correlation rarely holds true. Sizing for chest circumference often leaves waists uncomfortably tight, while sizing for waist creates swimming shoulders and excessive fabric everywhere else. "Portly" sizing categories offered by some brands are often outdated cuts that make you look larger rather than well-proportioned.

Additional issues include jacket backs that ride up when you sit down, creating bunching at the lower back and exposing your shirt. Armholes cut too low restrict arm movement and create billowing fabric under the arms.

Made-to-measure solutions:

MTM takes independent chest, natural waist, and trouser waist measurements, eliminating the forced correlation. Pattern adjustments include:

- Longer jacket length to balance proportions and ensure adequate seat coverage.

- Higher armholes for better drape and range of motion.

- Strategic dart placement that creates structure without tightness.

- Additional "swing" in the back panel allowing the jacket to drape naturally rather than pull.

Dunnio's approach specifically addresses these challenges. We measure your natural waist (smallest point of your torso) separately from your trouser waist (where pants actually sit on your body). Our pattern modifications add ease in the back panel while maintaining clean front lines. The result is comfort without the jacket-pulling effect that plagues off-the-rack suits for heavier builds.

Style recommendations:

- Single-breasted two-button jackets elongate the torso visually.

- Vertical patterns like pinstripes or subtle herringbone create lengthening effects.

- Avoid double-breasted styles which add visual width across the chest.

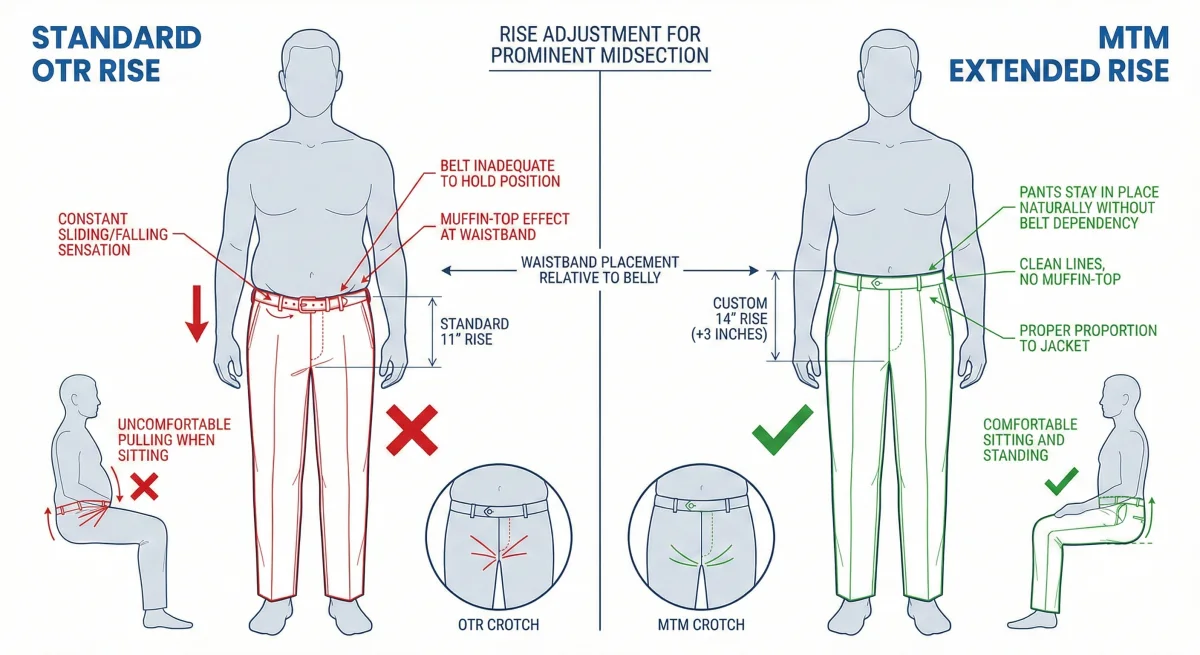

7.2. Made to measure vs off the rack suits for big-bellied men

The off-the-rack challenge:

Men carrying weight primarily in the midsection face a specific dilemma. When the waist fits correctly, shoulders swim in excess fabric. When shoulders fit properly, waists strain against buttons and create pulling across the midsection. Standard sizing cannot reconcile this contradiction.

Made-to-measure advantages:

MTM allows independent adjustment of the "drop" (difference between chest and waist measurements). While standard sizing might assume a 6-inch drop (42-inch chest with 36-inch waist), men with prominent midsections might need zero drop or even a "reverse drop" where waist exceeds chest.

Critical MTM adjustments include:

- Forward balance: The entire jacket pattern tilts slightly forward to accommodate a prominent belly. This prevents the jacket fronts from riding up and ensures the hem stays level.

- Trouser rise modification: The rise (distance from crotch seam to waistband) increases to allow pants to sit at your natural waist rather than struggling to stay up on your hips. This is far more comfortable and creates cleaner lines.

- Extended button placement: Buttons position slightly forward of center to reduce pulling stress and allow the jacket fronts to drape naturally over the midsection.

Style tips for proportion balance:

- Single-breasted two-button jackets (avoid three-button styles that visually shorten the torso).

- Subtle vertical patterns that draw the eye up and down rather than across.

- Consider three-piece suits where the vest provides midsection coverage and creates a streamlined silhouette.

If three-piece styling interests you, explore custom wedding vests that can be mixed and matched with jacket, vest and trouser combinations.

7.3. Made to measure vs off the rack suits for tall and slim, thin, or lean guys

Off-the-rack issues for tall, lean builds:

Standard "tall" sizes add overall length but make a crucial mistake: they also proportionally increase width. The result is sleeves long enough for your arms, but shoulders far too wide, creating a draped effect. Similarly, "tall" pants provide adequate inseam length but often feature excess fabric in the thighs and seat that billows awkwardly.

Another common issue is the forward pitch of sleeves. Taller men often have longer arms that hang slightly forward of their body rather than straight down. Off-the-rack patterns don't accommodate this, creating pulling at the back armhole and excess fabric in front.

Made-to-measure precision adjustments:

- Sleeve pitch modification: The sleeve attaches at a forward angle matching your natural arm hang, eliminating pulling and fabric bunching.

- Narrow shoulder width with appropriate sleeve length: These dimensions are adjusted independently, so you get 35-inch sleeves without 46-inch shoulders.

- Trouser leg taper without losing length: Pants can have a 34-inch inseam while tapering from a fitted thigh through to a narrow leg opening.

- Chest suppression: The jacket tapers from shoulder to waist more aggressively, avoiding the "swimming in fabric" effect.

Recommended details for tall, slim builds:

- Peak lapels add horizontal visual interest, balancing your vertical lines.

- Ticket pockets (small pocket above the right hip pocket) break up the long jacket front.

- Higher button stance (where the jacket buttons close) creates better proportion for longer torsos.

Create visual interest for taller frames

7.4. Additional body types

Athletic and muscular build:

- Challenge: Developed quads, glutes, and thighs from weight training don't fit standard trouser cuts. Sizing for leg circumference leaves enormous waists.

- MTM solution: "Athletic cut" patterns provide room in seat and thighs while maintaining a tapered waist. Jacket chest and shoulder measurements accommodate muscular upper bodies without creating tent-like waists.

Short men (under 5 feet 7 inches):

- Challenge: Standard "short" sizes are often still disproportionately long relative to overall height. Jacket length disrupts visual proportions, making you appear shorter.

- MTM solution: Shorter jacket length combined with higher button stance and slightly narrower lapels creates balanced proportions. Every measurement scales to your frame rather than simply subtracting inches from a standard pattern.

Broad shoulders with narrow waist:

- Challenge: Sizing for shoulder width creates massive excess fabric through the body.

- MTM solution: High chest suppression (dramatic taper from shoulder to waist). Raglan or modified sleeve attachment distributes fabric differently at the shoulder junction.

Posture-related adjustments:

Many men have forward-leaning shoulders, slight scoliosis, or one shoulder higher than the other. MTM accounts for these by adjusting collar height independently on each side, modifying sleeve pitch individually, and balancing jacket length to account for postural tilt.

Each body type benefits dramatically from made-to-measure construction in ways that off-the-rack suits simply cannot address. The ability to measure and adjust each dimension independently transforms fit from "acceptable with alterations" to "precisely correct from the first wearing.

8. When to choose MTM vs when to choose OTR

Understanding appropriate use cases for each option helps you make strategic decisions rather than defaulting to one approach universally.

Decision matrix

| Scenario | Best choice | Why |

| Wedding (groom) | Made-to-measure | Photographs last forever, fit must be perfect, precise color coordination with bridal party |

| Last-minute funeral | Off-the-rack | Need it same day, dark colors readily available in most stores |

| Building professional wardrobe | Made-to-measure | Cost-per-wear strongly favors MTM for frequent wearers |

| First suit ever (teenager) | Off-the-rack | Still growing, may outgrow quickly, learning preferences |

| Non-standard body type | Made-to-measure | OTR will never fit correctly without alterations exceeding MTM cost |

| Destination wedding (4+ months out) | Made-to-measure | Timeline allows proper fittings, climate-specific fabric selection possible |

| Experimenting with trends | Off-the-rack | Lower commitment for styles you might not wear long-term |

| Executive presence | Made-to-measure | Authority and competence projected through perfect fit |

Additional considerations:

- Budget versus value: If your absolute maximum budget is $300 and you need a suit within one week, off-the-rack is your only realistic option. However, if you can budget $400-600 and plan 6-8 weeks ahead, MTM provides superior long-term value.

- Frequency of use: Men wearing suits monthly or less might find off-the-rack acceptable, especially if their body type fits standard sizing reasonably well. Men wearing suits weekly or more should absolutely invest in MTM for the dramatic improvement in daily comfort and professional appearance.

- Special occasions: Any milestone eventweddings, major presentations, award ceremoniesjustifies MTM investment. The confidence boost from knowing you look your absolute best in a perfectly fitted suit is impossible to quantify but profoundly valuable.

Ready to experience perfect fit? Explore Dunnio's made-to-measure 2-piece suits options starting at $144, or 3-piece begin from $199. Free to designing your custom suit using the interactive 3D configurator.

9. The MTM process: what to expect with Dunnio Tailor

Understanding the timeline and steps demystifies the made-to-measure experience and sets realistic expectations.

Days 1-3: Consultation and measurement

Initial consultation can occur virtually via video call or in person if you're near a partner location. The consultant asks about your style preferences, typical use scenarios (corporate office, creative field, special events), climate considerations, and timeline requirements.

The measurement session captures 25+ precise dimensions including:

- Circumferences: chest, natural waist, trouser waist, seat (hips), bicep, wrist, thigh, knee, ankle

- Lengths: jacket length from collar to hem, sleeve from shoulder to wrist, trouser inseam and outseam

- Proportions: shoulder width, shoulder slope angle, back width

- Postural elements: forward lean, shoulder height differential, arm pitch

Dunnio creates a digital profile storing these measurements for future orders, so subsequent suits require only confirming measurements haven't significantly changed.

Days 4-7: Design and fabric selection

Using Dunnio's 3D visualization tool, you preview how different fabrics and design choices look on a digital model matching your build. This eliminates guesswork about how a small fabric swatch will appear as a completed suit.

Fabric selection from swatches representing Super 110s through Super 150s quality levels in various colors and patterns. Design customization includes:

- Lapel style (notch, peak, shawl) and width

- Button configuration (two-button, three-button) and material (horn, corozo nut, mother of pearl)

- Pocket styles (flap, patch, jetted)

- Lining fabric and color (traditional or bold contrast)

- Functional details (working sleeve buttonholes, ticket pocket, monogramming)

Days 8-18: Vietnamese artisan construction

After design finalization, your specifications transfer to our production facility where master tailors begin construction. The pattern is cut from your chosen fabric, canvas is hand-basted to jacket fronts, and construction proceeds using traditional techniques enhanced by modern quality control.

Vietnamese tailoring expertise combines centuries of fabric-working heritage with meticulous attention to detail. Our artisans' precision in hand-stitching, delicate needlework, and finishing details delivers results comparable to far more expensive Western bespoke operations while maintaining an accelerated production pace.

Days 19-21: Delivery and final adjustments

Completed suits undergo multi-point quality inspection before express international shipping. Most customers find the fit perfect upon first wearing due to our comprehensive measurement process. However, Dunnio accommodates minor adjustments if needed (usually limited to sleeve or pant length tweaks).

Unlike Western MTM services charging $1,200-$3,000 for similar construction and customization, Dunnio's Southeast Asian manufacturing base eliminates excessive retail markups without compromising quality. You receive the same half-canvas construction, quality fabrics, and measurement-based precision for $144-$600 in just 21 days.

For complete wardrobe coordination, you can also design custom trousers and custom vests independently using the 3D configurators, allowing mix-and-match combinations for maximum versatility.

10. Can off-the-rack suits be tailored? Realistic expectations

Many men hope that buying an off-the-rack suit and having it tailored will approximate made-to-measure results at lower cost. Understanding what alterations can and cannot accomplish prevents disappointment.

Easy alterations local tailors handle well:

- Sleeve shortening: Simple to execute, though lengthening is limited by available fabric inlay (typically 1-2 inches maximum).

- Pant hemming: Shortening pants is straightforward, lengthening depends on existing fabric allowance.

- Waist taking in: Tailors can reduce waist circumference by 1-2 inches by removing fabric from the center back seam or side seams.

Difficult and expensive alterations:

- Shoulder narrowing: Requires complete jacket deconstructionremoving sleeves, taking fabric from shoulders, reconstructing the entire upper jacket. Cost typically $150-250 and results are often imperfect.

- Jacket shortening: Disrupts the proportional relationship between pockets, vents, and hem. Difficult to execute invisibly. Cost $100-150.

- Sleeve lengthening: Only possible if sufficient fabric is folded inside the sleeve (called inlay). Most modern off-the-rack suits have minimal inlay, making lengthening impossible.

Impossible alterations:

- Changing shoulder slope angle: Requires completely rebuilding the jacket from a different pattern.

- Adjusting armhole height: Cannot be altered without full reconstruction.

- Modifying chest dimension significantly: Taking in more than 1-2 inches destroys the jacket's proportional balance.

Cost reality comparison

By the time you pay for extensive off-the-rack alterations addressing shoulders, jacket length, sleeve adjustments, and trouser modifications, you've often exceeded the cost of made-to-measure. Worse, you still settle for compromised fit in areas tailors cannot fix structurallyparticularly shoulders and armholes, which fundamentally determine how a jacket drapes on your frame.

The conclusion: Basic alterations (sleeves, hem, minor waist adjustment) make sense for off-the-rack suits. Extensive alterations approaching or exceeding $200 mean you should have chosen made-to-measure from the beginning.

11. Fabric and seasonal considerations

Selecting appropriate fabrics for climate and occasion significantly impacts comfort and suit longevity.

Seasonal fabric recommendations

Year-round versatility:

Super 110s to 120s tropical wool represents the most versatile fabric choice. High-twist construction creates breathability while maintaining structure. These fabrics travel well with minimal wrinkling and work across climate-controlled environments (offices, hotels, event venues) regardless of outdoor weather. For building a professional wardrobe, start with tropical wool in navy and charcoal gray before expanding to seasonal or occasion-specific fabrics.

Fabric weight explanation:

Weight measures grams per linear meter of fabric. Lighter weights (200-260g) provide summer breathability but may appear less substantial. Medium weights (280-320g) offer year-round functionality. Heavy weights (340-400g+) deliver winter warmth and create impressive drape but are uncomfortable in warm weather.

Special fabrics for specific needs:

- Summer destination weddings: Linen-wool blends provide temperature regulation essential for outdoor ceremonies in hot climates. Pure linen offers maximum breathability but wrinkles extensively. A 60% wool / 40% linen blend balances temperature control with wrinkle resistance.

- Winter formality: Flannel's brushed surface creates visual texture and retains warmth. The fabric photographs beautifully with a soft, matte finish that contrasts with high-gloss accessories.

- Business travel: Wrinkle-resistant tropical wools in Super 120s survive suitcase packing and long flights while maintaining crisp appearance.

Understanding fabric selection helps you specify the right materials during MTM consultation, ensuring your suit performs optimally for its intended use.

Explore dedicated linen wedding suit options

12. Special use case: the wedding suit decision

Weddings represent the single most common scenario where men seriously consider made to measure vs off the rack suits for men. Several factors make MTM particularly compelling for grooms and wedding parties.

12.1. Why weddings demand made-to-measure:

- Photography immortality: Your wedding photographs will be viewed for decadesby you, your spouse, children, and grandchildren. Ill-fitting suits with bunched shoulders or gaping collars become permanently preserved. MTM ensures you look your absolute best from every angle in hundreds of photographs.

- Color coordination precision: Matching or complementing the bridal party's colors requires precise fabric selection beyond what off-the-rack stores offer. MTM provides access to hundreds of fabrics, allowing exact color coordination whether you're matching bridesmaid dresses or creating intentional contrast.

- Comfort for 12+ hours: Wedding days start with morning preparation and extend through ceremony, photography sessions, cocktail hour, dinner, and dancing. A perfectly fitted suit allows unrestricted movement through all these activities without constantly adjusting your jacket or dealing with uncomfortable pressure points.

- Sentimental value: Many grooms preserve their wedding suits, wearing them on anniversaries or special occasions. A made-to-measure suit you genuinely love and that fits perfectly has lasting value beyond the wedding day.

12.2. Wedding timeline commonly recommendations:

- 8-12 months before wedding: Begin researching styles and consulting with MTM services. This allows leisurely decision-making without time pressure.

- 6 months before wedding: Finalize design and place order. This timing accommodates the 4-8 week production period plus buffer for any adjustments.

- 4 months before wedding: Suit delivery and first wearing to verify fit. This allows time for minor modifications if needed.

- 2 months before wedding: Final fitting to accommodate any body changes from stress, gym training, or diet adjustments many grooms undertake before weddings.

- 1 month before wedding: Final confirmation that everything fits perfectly and all accessories are coordinated.

12.3. Groomsmen group coordination:

Dunnio offers wedding party packages allowing style coordination while accommodating individual measurements. Each groomsman gets measured separately, ensuring every suit fits its wearer perfectly while maintaining consistent fabric, color, and design details across the group. Pricing starts at $144 per suit for groups of five or more, making MTM accessible for entire wedding parties at costs competitive with mid-range off-the-rack options.

For formal evening weddings requiring black-tie attire, custom tuxedos provide the ultimate in sophisticated styling. You can also design coordinating tuxedo shirts using the 3D configurator for complete ensemble control.

The wedding suit decision ultimately comes down to priorities. If you view wedding attire as a one-day costume to be discarded afterward, rental or cheap off-the-rack may suffice. If you value looking your absolute best on one of life's most significant days and want a suit you'll genuinely enjoy wearing for years to come, made-to-measure is the clear choice.

13. Common myths debunked

Misconceptions about made-to-measure prevent many men from exploring their best suiting option. Let's address the most common myths with factual corrections.

Myth 1: MTM suits take six months or longer

Reality: Modern made-to-measure services typically deliver in 4-8 weeks from order to delivery. This timeline includes measurement processing, fabric selection, pattern modification, construction, quality control, and international shipping. Bespoke tailoring requiring multiple fitting sessions takes 8-12+ weeks or longer. Dunnio's accelerated timeline is just 21 days with express production.

Myth 2: You need multiple fittings for made-to-measure

Reality: Modern MTM uses comprehensive initial measurements to produce suits that fit correctly the first time. Multiple fittings are characteristic of bespoke tailoring, where the suit is constructed progressively with intermediate try-ons. MTM's efficiency comes from applying decades of pattern-making knowledge to translate measurements into properly fitting garments without iterative adjustments.

Myth 3: MTM is only for wealthy people

Reality: Dunnio's made-to-measure suits start at $144less than many mid-range off-the-rack options and dramatically less than premium retail brands. Even Dunnio's luxury fabric options ($500-600) cost substantially less than the $1,200-3,000 charged by US and UK MTM services or the $5,000+ commanded by bespoke tailors.

Myth 4: Off-the-rack from luxury brands fits as well as MTM

Reality: A $2,000 Armani or Hugo Boss off-the-rack suit uses superior fabrics and better construction than a $400 department store suit, but it still relies on standard sizing. Better fabrics don't fix fundamental fit issues caused by your body's deviation from sizing templates. You can have a beautifully constructed jacket that doesn't fit your shoulders correctlythe construction quality can't compensate for pattern mismatch.

Myth 5: All made-to-measure services deliver the same quality

Reality:

Significant quality variation exists across MTM providers. Key differences include:

- Construction method: fused versus half-canvas versus full-canvas.

- Fabric sourcing: synthetic blends versus pure wool versus premium mills.

- Measurement process: basic chest/waist/inseam versus comprehensive 25+ dimension mapping.

- Tailoring origin: mass-production facilities versus skilled artisan workshops.

Always verify construction specifics, fabric quality, and understand where and how your suit will be made. Dunnio's transparency about Vietnamese artisan construction, half- and full-canvas options, and fabric sourcing allows informed decision-making.

Myth 6: You can't order MTM without visiting a physical location

Reality: Virtual consultations via video call work excellently for MTM ordering. Reputable services provide detailed measurement guides (often with instructional videos) allowing you to measure yourself accurately or have a friend assist. Some services partner with local tailors who can take measurements on their behalf. After your initial MTM order establishes your measurement profile, subsequent orders become even simpler.

14. How to get started with Dunnio MTM

Ready to move from off-the-rack compromise to made-to-measure precision? The process is straightforward and more accessible than most men expect.

Step 1: Explore styles and possibilities

Browse the men's custom suits collection at Dunnio Tailor to see the range of available styles, from classic business suits to modern slim fits. Use the 3D suit designer to experiment with different fabric colors, lapel styles, and design details. This visualization tool helps you understand how small design choices create dramatically different final appearances.

Step 2: Get measured accurately

Dunnio provides comprehensive measurement guides with video tutorials demonstrating proper technique. You'll need a cloth measuring tape and ideally a friend to assist with back width and jacket length measurements, which are difficult to self-measure accurately.

Key measurement tips:

- Wear only a thin t-shirt or dress shirt during measuring (not thick sweaters).

- Stand naturally without flexing or exaggerating posture.

- Keep the measuring tape snug but not tightit should lie flat against your body without compressing.

- Measure twice to verify accuracy, especially for critical dimensions like chest and jacket length.

Alternative: If you're uncomfortable self-measuring, Dunnio partners with tailors in major cities who can take measurements on our behalf. Contact customer service to find partner locations near you.

Step 3: Design your suit with complete customization

Select fabric from swatches representing various quality levels, weights, and patterns. Choose from dozens of customization options:

- Structural choices: two-button versus three-button front, single-breasted versus double-breasted, notch versus peak versus shawl lapels

- Functional details: number of interior pockets, ticket pocket, working sleeve buttonholes (surgeon's cuffs)

- Aesthetic details: lining fabric color and pattern, button material (horn, corozo nut, mother of pearl, contrast colors), contrast stitching on lapels and pockets

- Personalization: monogramming inside jacket pocket in various thread colors and fonts

The 3D configurator updates in real-time, showing you exactly how each choice affects the final appearance.

Step 4: Place order with transparent pricing

Dunnio's pricing is straightforward with no hidden fees:

- Entry-level suits: $144 (ideal for wedding parties, first MTM experience)

- Premium fabrics: $300-450

- Luxury options: $500-600

Secure payment processing and order tracking from placement through delivery. Customer service team available throughout the process to answer questions or refine design choices.

Step 5: Receive and enjoy your perfectly fitted suit

Delivery typically occurs 21 days after order placement. When your suit arrives, try it on in a well-lit room, ideally in front of a full-length mirror. The fit should be immediately comfortable without any pulling, gapping, or restriction. Minor adjustments to sleeve or pant length can be handled by local tailors if needed, though most customers find the fit perfect as delivered.

Care for your MTM suit properly and it will serve you for years:

- Hang on proper wooden suit hangers with wide, contoured shoulders

- Allow the suit to rest 24-48 hours between wears to let fabrics recover

- Brush with a clothes brush after wearing to remove surface dust

- Dry clean only when necessary (2-3 times per year maximum)wool is naturally odor resistant

Your perfect suit awaits. Start designing with Dunnio's interactive 3D configurator and discover why thousands of men worldwide choose made-to-measure over off-the-rack. Begin your custom journey today.

15. Frequently asked questions about made to measure vs off the rack suits

Q1: What is the main difference between made-to-measure and off-the-rack suits?

Made-to-measure suits are created by adjusting a base pattern according to your specific body measurements, typically recording 25 or more dimensions including posture and asymmetries. This customization ensures precise fit accounting for individual body characteristics. Off-the-rack suits are mass-produced in standard sizes (like 38R or 42L) based on average body templates. These generic sizes fit the theoretical average body but rarely fit real individuals perfectly without alterations.

Q2: How much does a made-to-measure suit cost?

Made-to-measure suit prices vary significantly by brand and manufacturing location. Dunnio Tailor offers MTM suits from $144 to $600 depending on fabric quality and customization level. US and UK MTM services typically charge $1,200 to $3,000 for comparable construction. Traditional bespoke tailoring starts at $5,000 and can exceed $15,000. The dramatic price difference reflects geographic manufacturing costs and retail markup structures rather than necessarily indicating quality differences.

Q3: How long does a made-to-measure suit take?

Most made-to-measure suits require 4 to 8 weeks from initial order to delivery. This timeline includes measurement processing, fabric selection confirmation, pattern modification, construction by skilled tailors, quality control inspection, and shipping. Dunnio's accelerated timeline is just 21 days for international express delivery. Bespoke suits requiring multiple fitting sessions take 8 to 12+ weeks or longer.

Q4: Are made-to-measure suits worth it for big-bellied men?

Absolutely yes. Made-to-measure is especially valuable for men carrying weight in the midsection because standard sizing cannot accommodate independent chest versus waist measurements. MTM allows customization of the "drop" (chest-to-waist difference), forward balance adjustment (jacket tilts forward to accommodate belly), and proper trouser rise so pants sit comfortably at natural waist rather than struggling to stay up on hips. These critical adjustments are impossible with off-the-rack construction.

Q5: Can you tailor an off-the-rack suit to fit like made-to-measure?

Only partially, and usually not cost-effectively. Tailors can easily adjust sleeve length, pant hems, and minor waist modifications (1-2 inches). However, critical fit elements like shoulder width, armhole height, and overall chest dimension cannot be altered without complete garment deconstruction costing $200-300 or more. Even then, results rarely match MTM precision because you're trying to force a wrong pattern to fit rather than starting with a pattern designed for your body. By the time alteration costs are added to an off-the-rack purchase, you've often exceeded MTM pricing while still accepting compromised fit.

Q6: What is the difference between fused and canvassed suit construction?

Fused suits use heat-activated glue to bond a stiffening interlining to the outer suit fabric. This mass-production technique is cost-effective but the glue degrades over 2-3 years from body heat, moisture, and dry cleaning, creating visible "bubbling" separation. Canvassed suits use horsehair or camel hair fabric that is hand-stitched to the jacket interior. This canvas "floats" between outer fabric and lining, allowing the jacket to mold to your body over time while maintaining structure. Half-canvas extends from shoulder to mid-chest; full-canvas extends shoulder to hem. Canvassed construction lasts 10-15+ years versus 2-3 years for fused suits.

Q7: How should a suit jacket fit?

A properly fitted suit jacket should meet these criteria: The shoulder seam ends exactly where your natural shoulder ends (not drooping past or pulling short of this point). When buttoned, two fingers fit comfortably between the fabric and your chest without pulling or billowing. Sleeves end at your wrist bone, showing 1 to 1.5 centimeters of shirt cuff. Jacket length reaches approximately the middle of your palm when arms hang naturally, covering roughly 75% of your seat. The collar sits flush against your shirt collar at the back neck without any gap. The jacket should allow unrestricted movement when reaching forward or raising arms.

Q8: Are made-to-measure suits good for tall and slim men?

Exceptionally well suited for tall, slim builds. Standard off-the-rack "tall" sizes add overall length but proportionally increase width as well, resulting in sleeves long enough but shoulders far too wide. Made-to-measure adjusts each dimension independently: appropriate sleeve length without excess shoulder width, adequate jacket and pant length without baggy fits, and chest suppression (tapering) to avoid the "swimming in fabric" appearance. MTM also accommodates the forward sleeve pitch common in tall men, eliminating the pulling sensation at back armholes that off-the-rack tall sizes create.

Q9: What suit fabric is best for weddings?

For spring and summer weddings, wool-silk blends in Super 120s quality offer subtle sheen that photographs beautifully while maintaining breathability for outdoor ceremonies. For fall and winter weddings, pure wool or wool-cashmere blends in Super 110s to 130s provide warmth and structure. Avoid Super 150s and finer wools for weddings despite their luxury feel—these ultra-fine fabrics are too delicate for active events involving dancing, hugging, and 12+ hours of continuous wearing. They wrinkle excessively and can develop stress tears at pressure points.

Q10: Why is Dunnio Tailor more affordable than western MTM brands?

Dunnio leverages Vietnamese manufacturing where master tailors possess exceptional precision in hand-stitching, embroidery, and detailed construction work developed through generations of tailoring heritage. By producing in Southeast Asia rather than Western countries, we eliminate excessive retail markups and inflated labor costs while maintaining identical construction quality. Our suits feature the same half-canvas or full-canvas construction, fabric sourcing, and comprehensive measurement-based fitting as US and UK MTM services charging $1,200 to $3,000. The primary difference is geographic manufacturing location, not quality or construction standards.

Q11: Can women get made-to-measure suits?

Yes, many MTM services including Dunnio create tailored suits for women. Female body proportions differ significantly from male proportions, making the measurement-based customization of MTM even more valuable for achieving proper fit. Construction and styling differ for women's suits (different button placement, dart locations, lapel proportions), but the fundamental MTM process remains the same: comprehensive measurements, pattern modification, and custom construction.

When choosing groom's suits at Dunnio Tailor, you will receive:

- Tailoring is based on personal measurements.

- Customize according to preferences.

- Instructions from a professional technical team.

- Tailored by skilled craftsmen.

- Fitting and adjusting as required.

- Fabric pattern options with a collection of more than 500 different fabric patterns.

- Free 720-day warranty.

- Free hangers and specialized storage bags.

- Support and shipping policies for international customers.

Hotline - WhatsApp: +84 968996668

Email: support@dunniotailor.com